STATE OF THE ART FACILITIES

Barcelona Innovation Center, Spain

Step into the heart of Euromed’s visionary endeavors with our state-of-the-art Innovation Center.

Established in 2018, this cutting-edge facility serves as the cornerstone of our commitment to

excellence in phytopharmaceutical innovation.

Located in Mollet del Vallès, Barcelona, Spain, our Innovation Center is the home of scientific

ingenuity and precision.

The high-tech building that houses our quality control and R&D laboratories embodies our

relentless focus on advancing pharmaceutical research and development.

With its elegant, modernist design and glass façade, the Innovation Center harnesses the power of natural light to optimize energy consumption and create an environment conducive to scientific discovery and sustainable practices.

Barcelona Plant, Spain

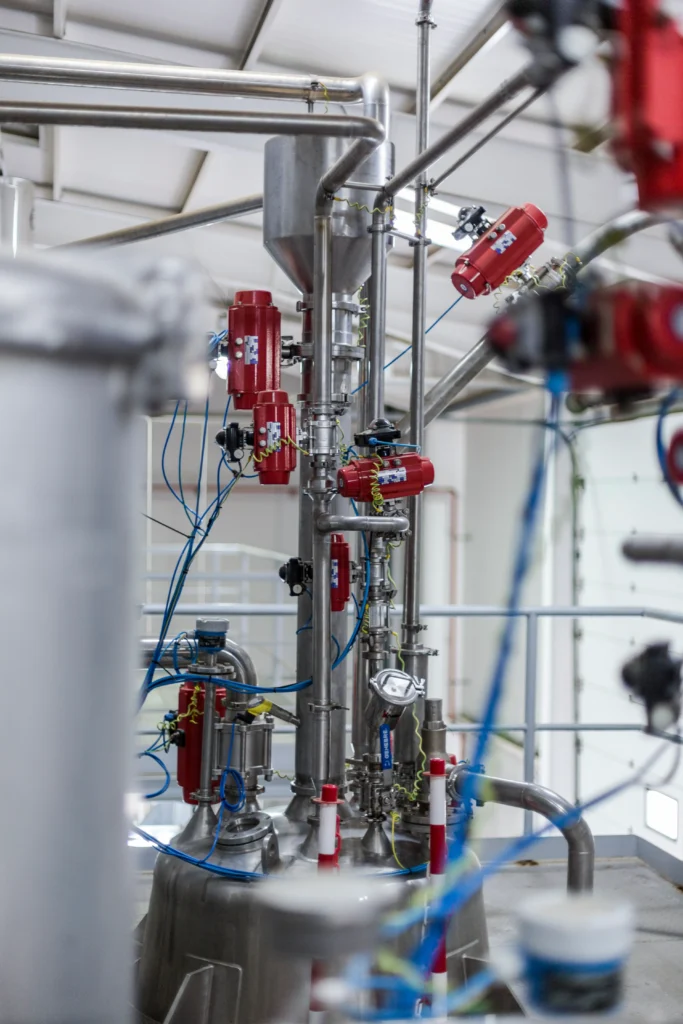

Founded in 1971 by the esteemed German phytopharmaceutical company Madaus, Euromed’s

manufacturing facility is a testament to our ongoing commitment to precision and innovation in pharmaceutical manufacturing.

This state-of-the-art facility has been carefully designed to comply with multiple quality standards, including Good Manufacturing Practice (GMP), ensuring the quality and safety of every product that bears the Euromed name. With a processing capacity of over 5,000 tons of biomass per year, we produce an extensive portfolio of pharmaceutical-grade products, including revered botanical extracts such as milk thistle and saw palmetto for the phytopharmaceutical and nutraceutical industries.

Our commitment to excellence goes beyond mere compliance with industry regulations. The

manufacturing facility is a center of constant modernization and improvement, driven by our

relentless pursuit of perfection and our dedication to meeting the demands of the pharmaceutical market.

Barcelona Warehouse, Spain

At Euromed, our warehouse is a cornerstone of our excellence in pharmaceutical logistics.

Designed to meet rigorous requirements, our warehouse serves as a vital hub for the storage

of both raw materials and finished extracts, to ensure the quality, safety and efficiency of stored

products.

The warehouse has appropriate storage conditions such as temperature, humidity and

ventilation to maintain the integrity of our raw materials and final extracts and ensure their

efficacy when they reach our customers.

By maintaining our own facilities for the storage of raw materials and finished extracts, we

achieve better control over the entire supply chain, which improves product quality and

increases operational efficiency. From quarantine to quality control release, every step of our products’ process is closely monitored to ensure our extracts meet the highest standards of

safety and efficacy.

Murcia Facilities, Spain

Acquired in 2017 and nestled in the bountiful region known as the Garden of Europe, our Murcia facility is a beacon of excellence in phytopharmaceutical manufacturing. Strategically located in the heart of Spain’s fruit and vegetable growing region, we have access to an abundance of high-quality raw materials sourced directly from local farms and orchards.

Our Murcia facilities are a harmonious blend of traditional extraction technologies and cutting-edge innovation. In addition to our traditional methods, we are proud to use the patent-pending Pure-Hydro Process® – a revolutionary water extraction technology that redefines the industry standard.

This innovative approach enables us to produce the highest quality botanical extracts, such as our Mediterranean Fruit and Vegetable Extracts.

Alongside our commitment to innovation, sustainability is at the heart of our operations in Murcia.

Taking advantage of the region’s abundant sunshine, a significant portion of our energy needs are covered by solar power, reducing our carbon footprint and underlining our commitment to

environmentally responsible practices.

Florida Procurement and Drying Facility

At Euromed, we understand the importance of maintaining the integrity of saw palmetto extract. In response to the adulteration challenges facing the industry, we set out to gain complete control over every aspect of the supply chain.

In 2004, this vision culminated in the opening of a new procurement and drying facility in Florida, strategically located near the saw palmetto fields. This investment in vertical integration allows us to monitor the entire production process, from field to final extract, ensuring the highest quality and authenticity at every step.

The key to preserving the potency of saw palmetto lies in the careful timing of the berry harvest and immediate proper drying of the raw material. Our on-site drying facility enables this critical step, ensuring the active principles of saw palmetto are preserved in their full potency for safe shipment to Spain.

This investment has proven critical to producing a genuine, high-quality saw palmetto berry extract, one that upholds Euromed’s commitment to excellence and integrity in botanical

extracts.

Euromed USA General Office

Since its inception in 1995, Euromed USA has been at the forefront of providing quality herbal solutions to the North American and Canadian markets. As a subsidiary of Euromed, our dedicated team is committed to serving the national market of the United States and Canada with excellence and integrity.

Salt Lake City Warehouse, USA

Located in Salt Lake City, Euromed’s US warehouse is a sign of the company’s commitment to

sustainable logistics. Partnering with a logistics provider, Euromed ensures seamless distribution throughout the United States and Canada.

Surrounded by the picturesque landscape of Utah, the strategically located warehouse benefits from the naturally dry climate of the surrounding mountains and can thus reduce energy consumption and thus the environmental impact – an important aspect for Euromed.